Once upon a time, in the land before PLM, product development was a bit like trying to assemble a spaceship with a blindfold on. Imagine engineers scribbling designs on napkins, manufacturers playing telephone with specifications, and sales teams selling products that were still figments of someone’s imagination. Chaos, my friends, was the order of the day.

The Dawn of PLM

In the swirling mists of the late 20th century, as computers started to infiltrate every nook and cranny of business, some bright sparks had an idea. “What if,” they mused, “we could manage the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal, all in one cohesive system?” Thus, the concept of Product Lifecycle Management (PLM) was born, not out of boredom, but out of sheer necessity.

The initial goal was simple: to stop the madness of disjointed information, lost designs, and the perpetual game of “who changed what and when?” PLM promised a world where data flowed like a serene river rather than a burst dam.

Why PLM was Born

- Complexity of Products: Products were getting more complex. Gone were the days of simple mechanical parts; now, there were electronics, software, and myriad regulations to consider. Managing this complexity required a system, not just a series of sticky notes.

- Globalization: Companies started spreading their wings across the globe. When your design team is in Germany, manufacturing in China, and customer support in India, you can’t just shout across the office for updates.

- Time-to-Market: The race to market became more intense. The faster you could get your product out without it falling apart or becoming obsolete upon arrival, the better your chances of winning the capitalist derby.

- Regulation and Compliance: With products affecting everything from the air we breathe to the planes we fly in, regulations became stricter. PLM systems helped track compliance at every stage, ensuring that products didn’t just work well but also played by the rules.

Enter Siemens Teamcenter

As PLM evolved from a novel concept to an industry necessity, several players entered the arena, but one name started to resonate like a battle cry in the world of manufacturing: Siemens Teamcenter.

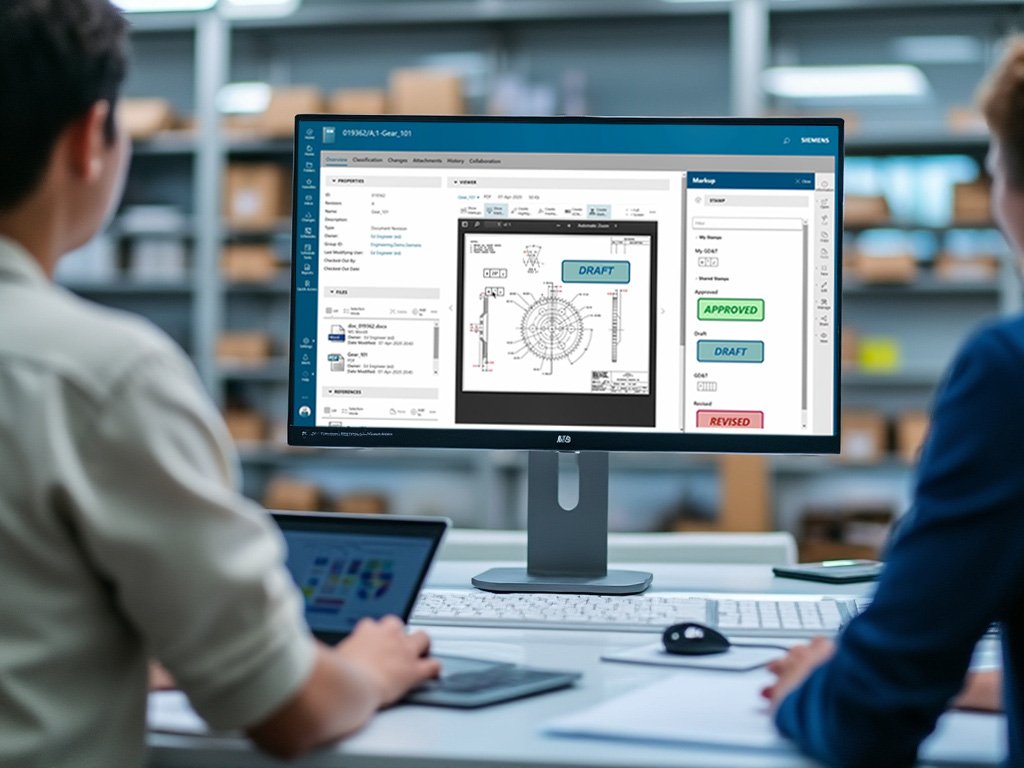

Siemens didn’t just step into the PLM world; they strutted in with a comprehensive suite known as Teamcenter. Why was this significant? Because Teamcenter wasn’t just about managing data; it was about integrating it. It allowed for:

- Unified Data Management: Everything in one place. No more hunting for the latest design file or the correct parts list.

- Collaboration: It made teams across the world feel like they were just across the table, with real-time collaboration tools.

- Scalability: Whether you were a startup or a multinational corporation, Teamcenter could scale to fit your chaos.

- Innovation: By streamlining processes, it freed up human brain space for what humans do best – innovating, not just administrating.

Teamcenter entered the scene not just as software but as a hero in the narrative of modern manufacturing, bringing with it a promise of order, efficiency, and perhaps most importantly, a bit of sanity in the complex world of product development.

So there you have it, the origin story of PLM, a tale of necessity, innovation, and the quest for order in the chaotic universe of product creation. And as our products continue to evolve, so too will the saga of PLM, with Siemens Teamcenter writing its chapters in bold, unified strokes.